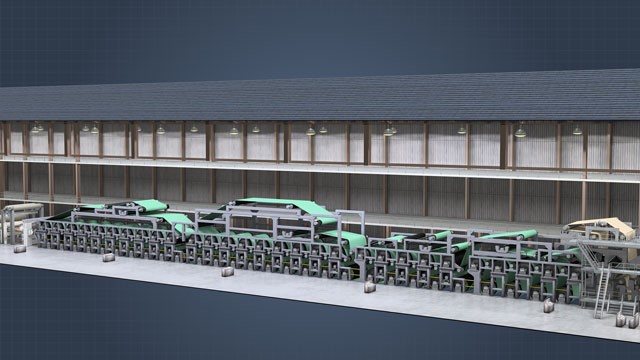

Dryer Felt System Operations

0.5 hrs. Online Course

Level: Intermediate

Average Rating:

Item #: RVCT-749

SME: Convergence Training

Level: Intermediate

Average Rating:

Item #: RVCT-749

SME: Convergence Training

NOTE: State license renewal information is provided as a convenience only and is subject to change at any time. It is the ultimate responsibility of the individual to be sure that he or she is meeting continuing education requirements for each license and corresponding renewal period. Information above was pulled on Saturday, December 13, 2025.